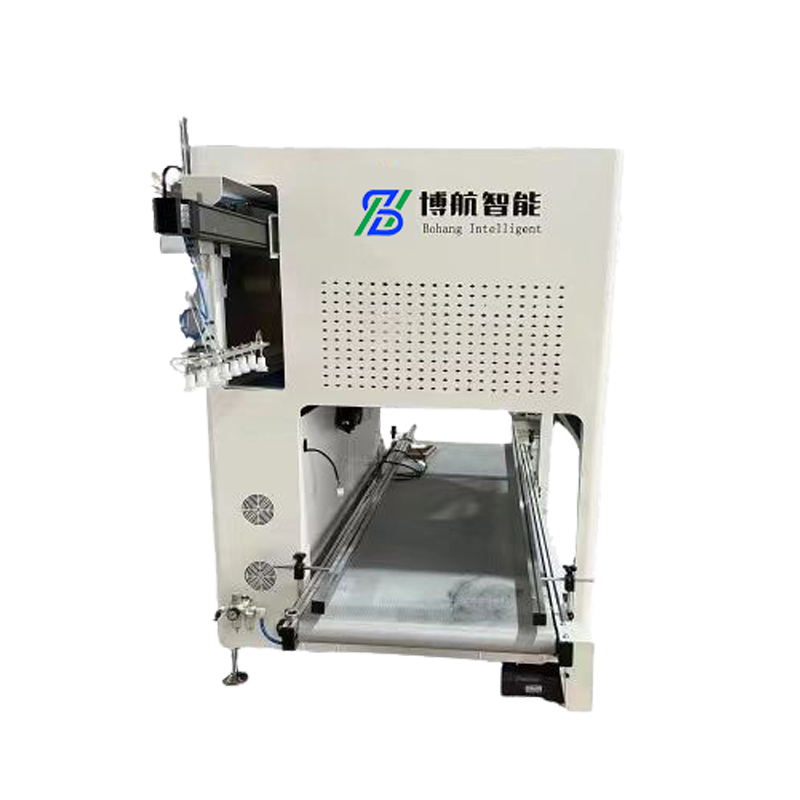

Automatic Bottle Cap Packing Machine

- Product Information

Automatic Bottle Cap Packing Machine

This machine is called automatic bottle cap packing machine. It is built to pack plastic bottle caps into a box neatly. After transporting completed caps through the conveyor belt, our bottle cap packing machine can automatically take and grasp them and then put them in an orderly manner in the box. Besides, it has the ability of automatically inserting protective film between each layer so as to maintain product surface smoothness. It significantly cuts down labor costs while boosting efficiency of production. This machinery has been designed with a rugged and efficient architecture that caters for diverse customer requirements. The Automatic Bottle Cap Packing Machine supplier guarantees that the devices are adjustable as per customer’s preference to obtain better results from these machines. And the organization ensures all customers are contented under its cost effective technological scope. We have wares which can save clients’ time and electrical power, boost production efficiency as well as reduce wage bills.

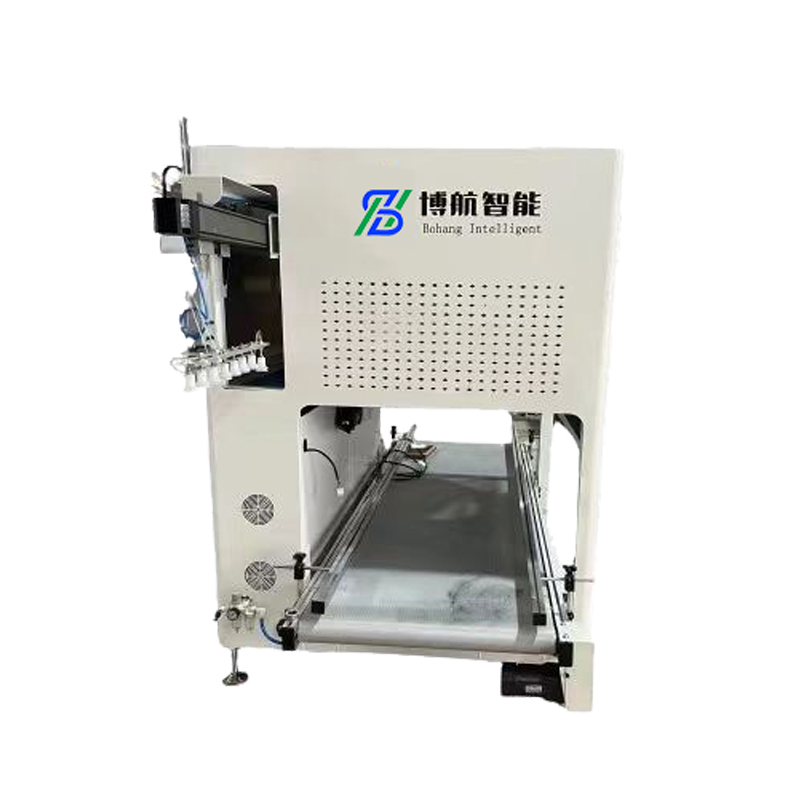

Automatic Bottle Cap Packing Machine Features:

1. Automated Operation: This machine performs actions like arranging, holding and positioning of bottle caps into boxes meant for packaging.

2. Protective Film Insertion: Introduces protective film amid layers so as to keep smoothness of surfaces intact.

3. Customization: It is adaptable such that it can be changed according to specific requirements hence ensuring high performance levels for ultimate client satisfaction.

4. Efficiency and Cost Savings: Enhances overall productivity by increasing production efficiency thus reducing labour costs involved.

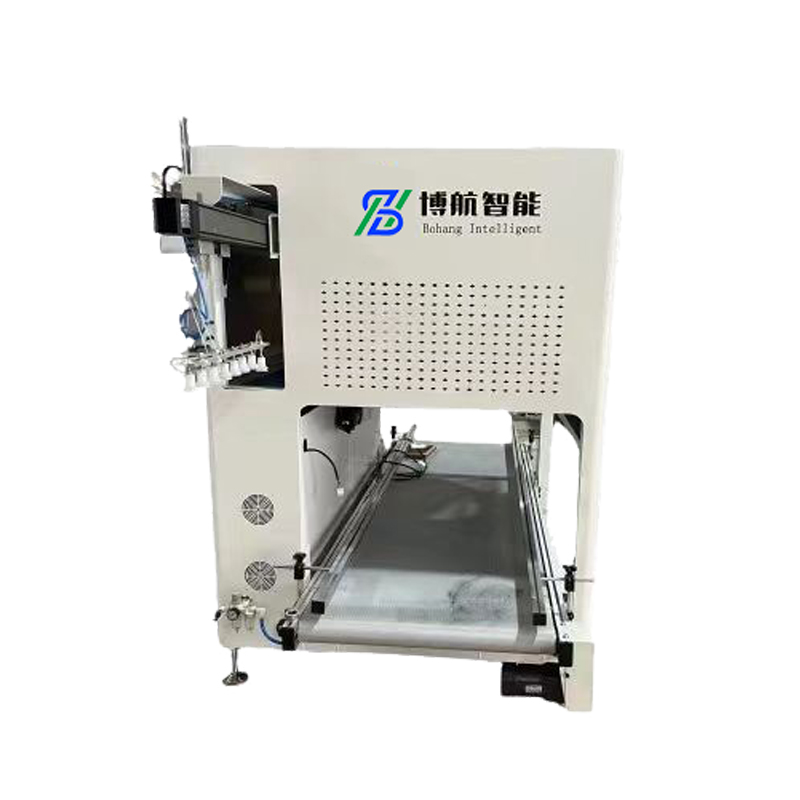

Automatic Bottle Cap Packing Machine Application:

1. Beverage Industry: This machine is suitable for beverage manufacturers who need to package bottle caps efficiently and hygienically. This ensures the cleanliness and the quality of the packages by ensuring that packing is done in an orderly, neat manner.

2. Pharmaceuticals: It is used in pharmaceutical production lines to pack medicine bottles’ caps. This maintains cleanliness and reduces contamination risks, thereby ensuring safety as well as compliance with industry regulations.

3. Cosmetics: These are suitable for cosmetic manufacturers with various cosmetic bottles that they need to put caps on. This improves packaging process efficiency, hence cutting down on manual labor while increasing output rate.

4. Food industries: It is used in the food industry to pack bottle caps utilized within food containers.

Automatic Bottle Cap Packing Machine FAQs:

What is the capacity of the Automatic Bottle Cap Packing Machine?

The machine can handle up to 10,000 bottle caps per hour, depending on the cap size and packaging configuration.

Can the Automatic Bottle Cap Packing Machine be customized to fit different sizes and types of bottle caps?

Yes, the machine can be customized to accommodate various sizes and types of bottle caps, ensuring flexibility for different production needs.

What are the main benefits of using this Automatic Bottle Cap Packing Machine?

The primary benefits include increased packaging efficiency, reduced labor costs, improved product quality, and minimized risk of contamination.

Is the Automatic Bottle Cap Packing Machine easy to operate and maintain?

Absolutely. The machine is designed with a user-friendly interface and comes with comprehensive manuals and training support, making it easy to operate and maintain.

Can this Automatic Bottle Cap Packing Machine integrate with existing production lines?

Yes, the machine is designed to be compatible with various production line setups and can be seamlessly integrated to enhance overall workflow efficiency.