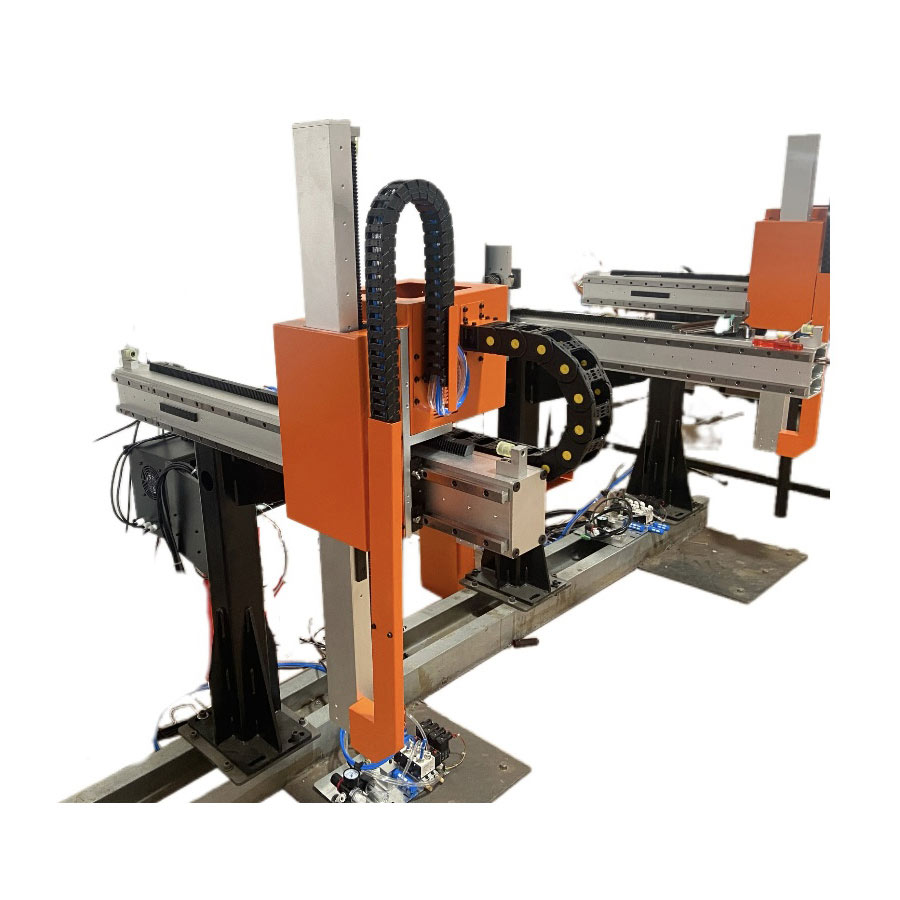

Injection Mold Machine Manipulator

- Product Information

Injection Mold machine Manipulator is an advanced addition to industrial automation especially in plastic injection molding processes. The injection mold manipulator can be easily integrated into plastic injection molding machines for better working efficiency. It cooperates with the process of forming by receiving end products of molding automatically. By automating functions such as stacking and sorting, this manipulator serves to shorten lead times, reduce laboriousness, and trim costs. Another significant feature of this product is that it suits any occasion appropriately. It could be configured according to customer’s requirements to deliver the best possible results. This supplier-orientation permits the manipulator to satisfy different purposes of multiple branches, which are achievable within reasonable technical limits. Our clients will save a lot on time and human resources by using this equipment; thus raising their productivity levels while minimizing general expenses. There cannot be any doubt that injection mold manipulator customize is one of the most important tools in present-day manufacturing industry because it promotes productivity and operational accuracy.

Injection Mold Machine Manipulator Features:

1. Efficiency through Automation: The purpose of this manipulator is to automate the retrieval and handling of products from injection molding machines thereby reducing the amount of manual work needed while increasing the efficiency of production.

2. The robot can be tailored to each customer's specifications hence optimizing its design for seamless operation with various types of moulding machines and production setups.

3. Reduced Labor Costs: By automating labor-intensive tasks such as product removal, stacking, and sorting, this gadget cuts down on human resource expenses thereby serving as a reasonable option for manufacturers.

4. Increased Production Throughput: This is done by ensuring fast and accurate handling of goods thus reducing downtimes and maximizing outputs in order to speed up the manufacturing process using a manipulator.

5. Enhanced Precision and Consistency: With an enhanced control system, it guarantees high levels of precision and uniformity when handling different items which are essential in mass production settings.

Injection Mold Machine Manipulator Application:

1. Plastic Injection Molding: Mainly used in plastic injection molding facilities to deal with different kinds of plastics such as automotive parts, consumer electronics and medical equipment components.

2. Large-Scale Manufacturing: Ideal for manufacturing environments which emphasize on high volumes and consistent production quality and accuracy.

3. Automated Assembly Lines: These can be incorporated into bigger automated assembly lines that enable movement of the components as well as their placement at various stages in the production process.

4. Quality Control Systems: Commonly linked with quality control systems to guarantee only products meeting specific standards are moved ahead in the production line.

5. High-Variety Production Runs: Particularly effective in environments where there is frequent changeover on product types and sizes during manufacturing, requiring systems that are adaptable and flexible.

Injection Mold Machine Manipulator FAQs:

What are the customization options available for the Injection Mold Machine Manipulator?

We offer extensive customization options including arm length, payload capacity, control systems, and software integration to meet specific production needs and seamlessly integrate with existing machinery.

How does this manipulator improve production efficiency?

The manipulator automates the removal, stacking, and sorting of products from injection molding machines, which significantly speeds up the process, reduces human error, and increases overall throughput.

What are the safety features of this manipulator?

Safety is paramount in our design. The manipulator is equipped with built-in sensors that detect human presence, emergency stop features, and programmable limits to ensure safe operation in busy production environments.

Can this manipulator handle different types of materials?

Yes, it is designed to handle a variety of materials commonly used in injection molding processes, including plastics, composites, and some metals, depending on the customization of the end effector.

Is the software used in the manipulator compatible with other industrial automation systems?

Yes, the software is highly compatible and can be integrated with most industrial automation systems. It supports various communication protocols and can be tailored to link with your existing factory management software.